|

TechnoPHILEPlugged-in stuff. Content related to technology, hacking, electronics, and software. |

|

TechnoPHOBEUnplugged stuff. Non-tech, primitive/ancient tools, techniques, or archaic tech. |

|---|

Serv O’Beer

by Steve Struebing on Dec.31, 2008, under technoPHILE

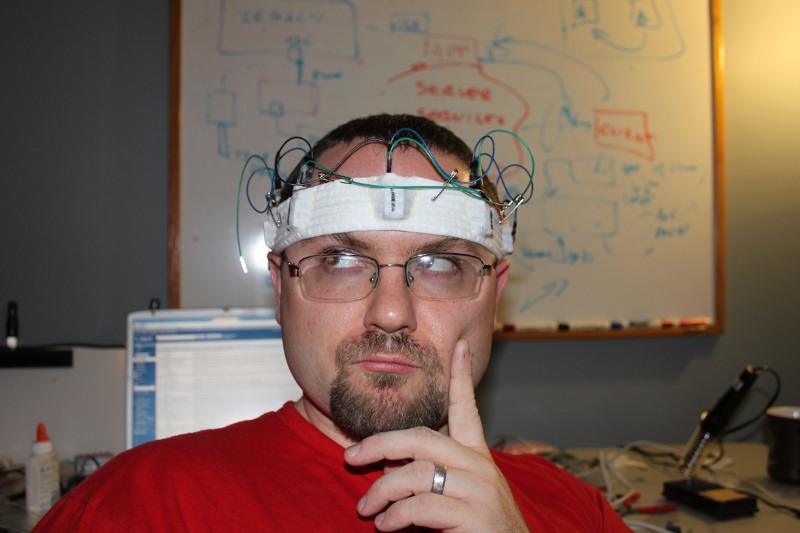

With New Years fast approaching, I wanted to make a project that allows for the perfect pour and take out all of that physical work. Using Construx as the mechanical platform, a servo driving the action, and ioBridge controlling the system, I was to achieve “the perfect pour” controlled with the turning of my iPhone (using the accelerometer feedback determing the screen orientation). We’ve all seen the iBeer application on the iPhone, and now I can actually enjoy the IPA rather than just virtually pouring!

httpv://www.youtube.com/watch?v=NtUyzQBNT3k

UPDATE:

The information about this project can be found at Instructables.com including steps to make it. Also, you will see the project was picked up at Gizmodo, Engadget, ioBridge Projects, and the fine folks over at MAKE.

Weaving a Quiver

by Steve Struebing on Dec.20, 2008, under technoPHOBE

Why Weave?

So you may rightly be asking yourself “What in this dude’s right mind does he want to have to do with weaving? Doesn’t he have anything better to do?”. A fair question. However, let me take a moment to defend myself. Really the catalyst of all this, and a lot of the technoPhobe content, stems from a random meeting at a bar. I had just finished the longbow project, and was in Wolfboro Tavern in New Hampshire enjoying some drinks with my stepfather. Somehow we got to talking to a guy next to us who was ravenously attacking a plate of wings like he had never eaten before.

“Wifes a vegeterian. She’s out of town, so this is one of the few shots I get unless I am teaching class.” , he says.

Inquisitively I ask “Class?” What do you teach?”

“Primitive survival skills.”, he adds as another defleshed wing bone hits the plate.

Needless to say, I had many other questions for him. We talked about longbows, firebuilding, etc. Before he rolled out for the night, he turned me onto this book “Caveman Chemistry” (author Kevin M. Dunn. A great book I may add now from experience. I have bought 4 copies for friends). There is a chapter on spinning yarn, and hence my desire to be able to spin, and weave, something of purpose. Spinning I will cover later.

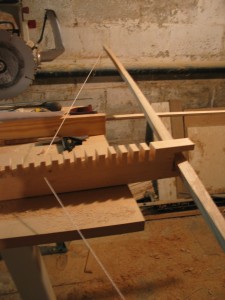

The Loom

The first step is to buy (or build from Construx) a loom. Next, you have to “warp the loom”. This is done by running yarn lengthwise on the loom. By alternating direction in a figure 8 type fashion, you can create what is called a “natural shed” against the loom. No need to bore you with details.

Loom built of Construx

As mentioned, warping yarns are the long yarns that run the length of the loom (in our case, this could change depending on the loom). The weft yarns to back and forth.

There are all kinds of interesting patterns that you can make by changing the pattern of which warp yarns you go over and under. Alternating each (over, under, over, under) is called a “linen weave”. (Here in this illustration, + is over the warp, -is under.

+ – + – + – + – + – + – + – + – + – + – + – +

– + – + – + – + – + – + – + – + – + – + – + –

+ – + – + – + – + – + – + – + – + – + – + – +

– + – + – + – + – + – + – + – + – + – + – + –

Another example is the twill weave (under, over, over, under, over, over). Note the diagonal bands taking shape in the twill.

– – + – – + – – + – – + – – + – – + – – + – – +

+ – – + – – + – – + – – + – – + – -+ – – + – – +

– – + – – + – – + – – + – – + – – + – – + – – + –

+ – – + – – + – – + – – + – – + – – + – – + – – +

Here the shed stick is opening the "natural shed"

As a kid, you may have had a loom and used a needle or shuttle to go over and under the warp yarns. Well, obviously a better system existed. Using a device, you can mechanically raise the odd and even warp yarns, and just shoot the shuttle down the gap (known as the shed). The one raising the “natural shed” (the yarns naturally raised by the loom) is called the “shed stick”.

Here the "heddling stick" raises the alternate warp yarns opposite the natural shed.

The implement that raises the alternative warp yarns is called the “heddling stick”. There are also looms (one of which I will no doubt build as I have acquired the wood for it) which achieve the heddling action as a function of the loom itself. This is called a “rigid heddle loom”.

Using a fork in a whipping movement to compress the weft yarn

So by simply alternating raising the natural shed, running the shuttle down, raising the heddling stick, bringing the shuttle back (rinse and repeat), you achieve this linen weave. Each couple of rows we would use a fork to tighten the weave.

Here are some additional shots showing cleverness from my technoPhobe cohort in finishing the seam with a needle, working the leather base, and finishing the product.

Detail of the opened shed

Almost 50%

Finally done. This needs to be automated.

Sewing the seam

Borrowing the innovation of a needle

Finished at last

Note the leather guard at the opening to prevent damage, and the leather base that my friend made very successfully.

Now, all I need are some arrows, and I can live off the land. Provided the land has an XBox 360, and a power supply.

Building a Longbow

by Steve Struebing on Apr.09, 2008, under technoPHOBE

Longbow on tillering stick

Test Firing the Longbow

httpv://www.youtube.com/watch?v=LkgmPqN8Q54

The Short of Longbow Building

There are many factors that affect the efficiency of the longbow. All things being equal, a heavier draw weight (the strength needed to pull the bow back to full draw length) yeilds a faster arrow. However, if the bow does not effectively transfer that energy quickly and effctively into the arrow, a lower draw weight bow will outshoot a heavier one.

- Draw Weight – as noted above – the heavier, the faster the arrow

- Draw Length– The longer the bow, the faster the arrow.

- String Height– This one may feel counter-intuitive, but a lower strung bow makes for a faster arrow.

There are many other factors regarding where the mass of the limbs is located, internal friction in the limbs, arrow mass, etc. If you are interested in all of those details, I leave it to the masters in “The Traditional Bowyer’s Bible” (yes, there are 4 volumes). Its easy to follow, and you’ll be amazed how complex this little machine is. Also, its amazing how the ancient cultures “happened” upon massive improvements such as the recurve, composite bow, and others. Neat stuff, but I digress.

Starting to Build

There is much to know about what to look for in the wood you use. It’s an artform in and of itself. Osage Orange and Yew woods are great traditional ones to use. For us, we used ash. To keep it simple here, the tree lays down a new ring each year (yeah, remember looking at cross sections and counting rings as a kid, right?). Ideally you want the “back” of the bow, which is the side facing away from the archer, to be one continuous growth ring. The back of the bow is under significant tension (where the “belly”, or side facing the archer, is in compression) so a single ring affords by far the best tensile strength. In this picture, we have cut the wood (called “the stave”) at an angle aligning with the growth rings to give us good strength.

Note the light and dark bands

Natural Born Tiller

We have created our profile of the bow, and marked off the taper to an appopriate notch size. Warm up the rasps and planes, because the hard work is about to begin.

Here we mark off the taper to the notches to be planed off.

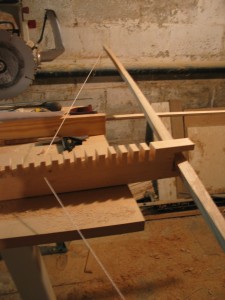

This is where the real work begins. This is the process of “tillering” the bow. Once you have done what you can to get the back of the bow to a single growth ring (ours was not perfect, but good enough we hoped) the long process of reducing the belly begins. Using a rasp and plane (many bowyers are adept with a drawknife) we reduce the wood to it starts to bend, and place it on a “tillering stick”. This holds the bow in place and has inch by inch notches to draw the bow longer and longer back.

Here with the rasp, plane, and drawknife is the real work.

Longbow on tillering stick

As we plane and put the bow on the tillering stick, we are looking for places where the bow bends unevenly. That indicates there is too much wood on a limb of the bow, and needs to be balanced. Here is an example of a “hinge” that has developed due to uneven tiller.

Note the hinge that has developed on the bow. More work needed here.

Here the hinge has been tillered out of the bow.

Also you can get a sense of how the tiller is going doing by drawing the bow yourself. This bow was damn heavy at this point.

Testing the draw weight of the bow.

Finishing and Testing

After 8 hours of tillering (I don’t know what the average is, but I doubt it should have taken that long), we used a bathroom scale to test the draw weight at a given draw length. For us, we ended up with 45 pounds at 28 inches draw. Not a heavy bow (some of old English warbows were 100 pounds plus. Forget that image of little wussy archers in tights), but still seemed functional for a first attempt.

Testing the weight on the scale

Successfully firing the bow